Thursday 21 April 2011

Wednesday 20 April 2011

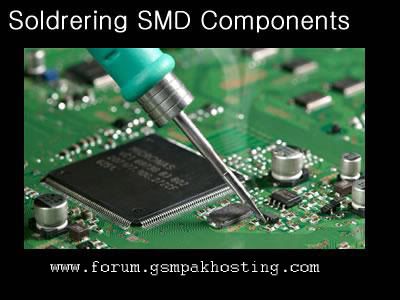

Soldering and Desoldering Tools

Soldering and Desoldering Tools

Soldering Iron

A soldering iron is a tool normally used for applying heat to two or more adjoining metal parts such that solder may melt and flow between those parts, binding them securely, conductively and hermetically.

A soldering iron is composed of a heated metal tip and an insulated handle. Heating is often achieved electrically, by passing an electrical current (supplied through an electrical cord or battery cables) through the resistive material of a heating element. Another heating method includes combustion of a suitable gas, which can either be delivered through a tank mounted on the iron (flameless), or through an external flame.

Some soldering irons heat up and cool down in a few seconds, while others may take several minutes.

Soldering LEAD

Soldering lead is used to bond or connect electronic components.

Solder is a fusible metal alloy with a melting point or melting range of 90 to 450 degree Celsius (190 to 840 °F), used in a process called soldering where it is melted to join metallic surfaces. It is especially useful in electronics . Alloys that melt between 180 and 190 °C (360 and 370 °F) are the most commonly used. By definition, using alloys with melting point above 450 °C (840 °F) is called brazing. Solder can contain lead and/or flux but in many applications solder is now lead free.

While it is possible to do some wiring without soldering connections, soldering is the preferred approach. Proper soldering is easy with the right tools and techniques. One item that is critical is the right solder. DO NOT use the environmentally friendly lead free solders, they don't work worth a damn. Even in carefully controlled industrial conditions, lead free solders produce inferior connections. As much as the politicians backed by environmentalists would like to, they can't legislate metallurgy.

Soldering Paste

Solder paste (or solder cream) is used for connecting the terminations of integrated chip packages with land patterns on the printed circuit board. The paste is applied to the lands by printing the solder using a stencil, while other methods like screening and dispensing are also used. A majority of defects in mount assemblies are caused due to the issues in printing process or due to defects in the solder paste. An electronics manufacturer needs to have a good idea about the printing process, specifically the paste characteristics, to avoid reworking costs on the assemblies.

Characteristics of the paste, like viscosity and flux levels, need to be monitored periodically by performing in-house tests.

Soldering flux

Soldering flux is just a safe, convenient acid for dissolving the oxide skin off the metal

you want your solder to wet well. Also dissolves oxide off the liquid solder, making it

less crusty and therefore more shiny.

"Acid" flux is the stronger class of flux; it has something like hydrochloric acid in

it. (The paste form has zinc chloride.)

This is good for making difficult oxides dissolve so difficult metals like stainless

steel can be solder-wetted.

But the acid can hang around later trying to corrode the metal it just cleaned for you.

So for electronic stuff we mostly do not use it.

If we do, we scrub it off with things like toothbrush, water, soap, alcohol, baking soda,

to minimize acid residues.

The flux built into most solder wire is called rosin flux.

I think it is an organic acid (so is vinegar, and tart-tasting "citric acid"),

stuck onto larger molecules that melt only at soldering temperatures.

That is the clear yellow-brownish plaque that sits on the solder's surface when you are

done.

It does the same stuff as acid flux, but it is milder two ways.

It is only strong enough to reduce weakly oxidizable metals like copper, tin, lead,

silver.

So it is just strong enough for electronics use, but not for soldering to stainless

steel or iron or anything with chrome or aluminum.

And rosin-flux goes back to its plastic-like solid form after use, so it does not act

very corrosive to the metals later on.

So we do not need to clean it away carefully.

It can be cleaned away if you want to work at it, with brush-scrubbing and the right

"polar solvents".

"Flux remover" is sold in spray-cans for this. Rubbing alcohol with a dash of dish-soap

sort of works for me.

Try it and see what it looks like.

Soldering Wick

A solder wick (also desoldering wick or desoldering braid) is a tool for removing solder from any solder joint. Usually, it is a roll of fine, braided 18 to 42 AWG wire, typically oxygen free copper, which has been treated with a rosin solder flux.

Close up to a piece of solder wick

Close up to the netting of a solder wick

To remove solder with it, one presses the wick onto the solder joint to be removed and then heats the wick portion that is on the connection with the tip of a soldering iron. As the rosin melts onto the wick and the connection and the solder reaches its melting point the solder rushes via capillary action onto the clean copper braid. Once everything has melted and the solder fuses with the braided copper, the wick is lifted along with the solder and is then cut off and disposed of.

Subscribe to:

Posts (Atom)